Safety valves are valves that allow to regulate and control the specific overpressure of liquids and gases. GMPTEC safety valves are available in standard sizes of up to 2’’, are CE certified and compliant to the PED Pressure Equipment Directive. Available types of connections are Tri-Clamp, NPT thread, threaded ends and a variety of flanges. The maximum response pressure of our safety valves is up to 40 bar, respectively up to 16 bar for our pharmaceutical valves.

Safety Valves

Description

GMP compliant Safety Valves

GMPTEC safety valves are spring-loaded and made of different steel alloys and gasket materials, depending on the type. Right angle safety valves react to one-sided overpressure within the pipeline. In the initial position, a mechanical spring pushes the closing piston into the sealing surface of the valves inlet. The medium is held back until the pressure is high enough to push back the spring. Then, the gas or also liquid flows directly into a discharge case. The setting of the response pressure can be adjusted by using different spring strenghts.

Therefore, the required response pressure has to be known beforehand. Due to the usage of either metallic or soft seals, the working temperature has a very broad range from -50 °C to +200 °C. Safety valves are not only being used in cGMP processes. They are a necessity in every overpressure systems, in order to guarantee the safety of all operators and also employees.

If you have different requirements regarding the flow control within your system, you can also find pressure valves and various process valves – based on flat diaphragm or radial diaphragm technology – within our portfolio.

GMPTEC safety valves compliant to the Pressure Equipment Directive. This guideline describes and determines the requirements applicable for pressure components and equipment. It is binding for all member states of the European Union and is internationally known as the “Pressure Equipment Directive” (PED).

Connection types of the Safety Valves

- Aseptic flanges e.g. DIN 11864-2

- Flanges e.g. DIN 2633 (PN16)

- Threaded ends e.g. DIN 11851

- Clamp connections e.g. DIN 32676

Further types of Valves

- Pressure regulation valve

- Pressure minimization valve

- Relief valve

- Pre-pressure control

- Ventilation valve

- Overpressure valve

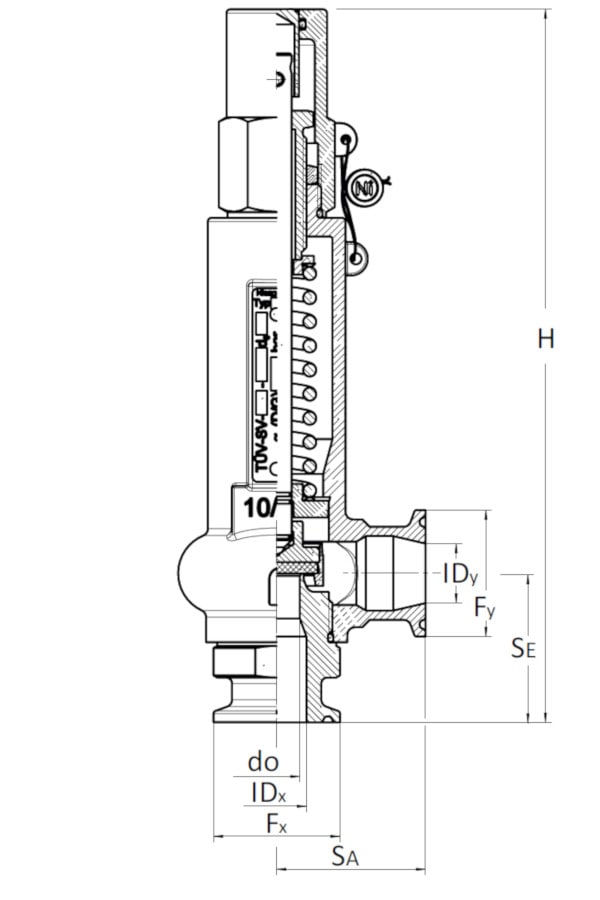

Available dimensions of the Tri-Clamp Safety Valve

| Size | IDx | Fx | do | IDy | Fy | H | SA | SE |

|---|---|---|---|---|---|---|---|---|

| 1/2″ | 9.4 | 25 | 8 | 15.75 | 25 | 19 | 40 | 40 |

| 3/4″ | 15.75 | 25 | 10 | 15.75 | 25 | 19 | 40 | 40 |

| 1″ | 22.1 | 50.5 | 16 | 22.1 | 50.5 | 22.5 | 50 | 50 |

| 1 1/2″ | 34.8 | 50.5 | 16 | 34.8 | 50.5 | 22.2 | 50 | 50 |

| 2″ | 47.5 | 64 | 16 | 47.5 | 64 | 22.5 | 50 | 50 |

(Further sizes and shapes are available on request)

cGMP Safety Valves are compliant to:

- USP Class VI 121°C

- Working temperature -50°C to 200°C

- Safety Valve sizes ½“ – 2“

- Response pressure of 0.10 bar – 16 bar

- Weight approx. 7,1 – 13,5 Kg depending on the size

- Soft sealing

- PED Pressure Equipment Directive2014/68/EU

- Surface quality SF1 (materials in contact to the product)

- Optional certification of the surface 2.2

- Free of animal components BSE/TSE

- Inlet body and sealing material 1.4571

- Inlet body and sealing material also available in 1.4404 and 1.4435

- VdTÜV data sheet

- AD 2000 data sheet A 2

- CE conformity

- EAC