The product category of plastic fabrication includes a whole variety of different things, which all can be used as tools for GMP processes. The product range includes simple screw-wrenches, whiteboards and even individual workstations and dollies.

The specialty is, that all these products are mainly made of plastic, which perfectly suits the needs of areas where cleanness, high quality of materials, low weight and a chemical resistance are of high importance.

Plastic Fabrication

Description

Information about Plastic Fabrication

GMPTEC plastic fabrications offer you a broad range of individual options and solutions for every process. Those fabrications are usually produced according to the ideas and requirements of each individual customer, in order to achieve the best suiting product for their cause and a solution that convinces on every level.

The design hardly has any limitations. The fabrications can be adapted for every pharmaceutical and also biotechnological production.

Examples of possible plastic fabrications

- Tools

- Whiteboards

- Bottle holder

- Dollies

- Workstations

- Holders for tubing spools

- Storage boxes

- Not only transport trolleys for bags, but also transport trolleys for barrels

- Light table for inspection and quality control

- Cases and housings

The basic material is usually polypropylene, but we also offer additional materials and even colored applications on request.

Of cause, we also offer individual housings or cases for existing equipment. This allows to install several devices into one housing made of plastic, which can then be placed on different modular workstations or even on transport carts.

The development of such GMP plastic fabrications is always done in cooperation with the final customer. You will acquire everything from one source and also exactly according to your requirements – from first sketches, to technical drawings, to prototypes, to the final product.

The plastic fabrications offer numerous advantages compared to similar solutions made of stainless steel. For instance, they are less heavy, which is especially important for dollies or also mobile workstations. It highly reduces the stress and risk of injury for the employees during handling. Moreover, plastic fabrications are easy to clean, have a good chemical resistance and also protect against electric charging due to its isolation. Especially when it comes to terms of production, a solution made of plastic can be produced much fast and more economically than a comparable product made of stainless steel.

Features and Properties of Plastic Fabrications

- Broad Range of Products

- Individual Solutions

- Great Cleaning Capability

- Low Weight

- Not only FDA compliant, but also USP Class VI compliant

- Good Chemical Resistance

Processes and Applications

- GMP Processes

- Quality Control

- Work Preparation

- Pharmaceutical Production

- Filling Applications

- Sampling Processes

- Filtration Applications

- Cell Cultivation, Harvest and also Fermentation

Are you looking for an individual plastic fabrication?

Feel free to contact us – we will find a solution!

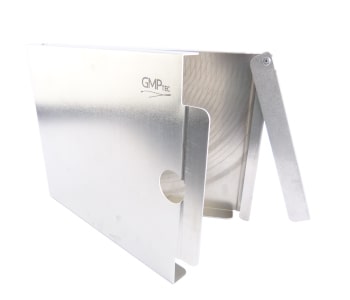

Details and information about the bottle holder with handle

A customer was looking for a possibility to safely transport multiple filled plastic bottles at the same time from one area to another.

None of the available solutions on the market could meet the requirements. That’s why an individual bottle holder with handle was designed. It is made of USP class VI compliant polypropylene, has space for five bottles and the handle allows to easily carry it with one hand only. This way, a single employee can transport ten bottles at once, for which he had to walk several times before.

Details and information about the trolley with storage space

The customer was looking for a trolley for transporting and storing components and equipment within his pharmaceutical production.

In every other industry sector a regular cart with a wooden work surface would probably be fine. But within a pharmaceutical production environment, a different solution was needed.

A cart made of stainless steel would be possible and could meet the requirements. However, the material would be too heavy and the production way too complex and costly. Also, a cart completely made of stainless steel could damage production equipment pretty easily in case of unintended contact with its surroundings.

The solution was a cart made entirely of USP Class VI conform polypropylene. It has three levels to store and transport components, consumable materials and more. It is light, easy to handle and the surfaces can be cleaned well. A solution that convinces on every level and meets all of our customers requirements.