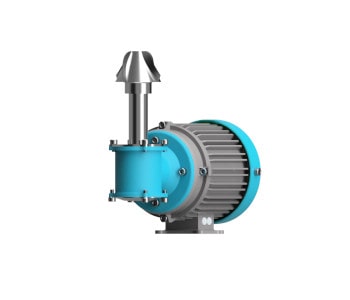

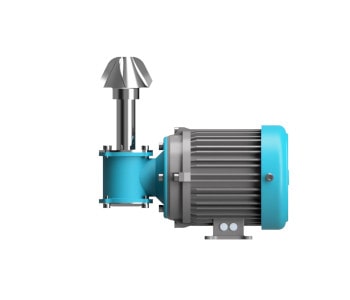

GMP compliant burst discs are being used in the food, cosmetic and pharmaceutical industry. Due to thin-walled small metal plates respectively membranes, the pressure can be absorbed up to a certain level without leakage or loss of pressure. In case the pressure rises unwantedly or caused by unknown effects within the assembly or vessel, the metal membrane within the burst disc bursts immediately.

Burst Discs

Description

Burst Discs function and application

Burst discs are made of a thin metal membrane which has a special shape and is slightly arched. It is cased in a regular Tri-Clamp gasket. Outside of the gasket is another thin metal sheet. It is straight, square shaped and needed for marking the burst disc. This marking is visible at the outside and contains information like type, bursting pressure, size and batch number.

Another alternative is the burst disc indicator. Additionally, it has a cable at the identification plate, which sends an electrical signal as soon as the disc bursts. When the disc is damaged, the electric circuit, which usually runs through a copper film within the disc, gets interrupted. Burst disc indicators can easily be integrated in every SPS control system and their programming.

Moreover, we offer burst discs suitable for vacuum which burst at a pressure range from 0.4 to 0.499 bar.

Further explanations regarding burst discs can be found on the following website

Are you searching for a specific burst disc? Send us an inquiry and we’ll definitely find the perfect solution for you! An overview of all available burst discs is available upon request.

Applications for the Burst Discs:

- Mobil vessels

- Preparation vessel

- Pressure impinging on tubing and pipes

- CIP/SIP process

- Nitrogen filled vessels

- Formulation

Burst Discs are compliant to:

- USP Class VI

- FDA

- BSE/TSE

- EU1935/2004

- PED guidelines for pressure equipment

- 3A Standard

- ASME

- CE

- CRN/ EAC/ KOSHA /SELA

- Packaged within a cleanroom

- SIP/CIP capable

- Optional 2.2 certification of the surface material

- Optional electro polished

- Gasket materials: EPDM, Silicone, PTFE, Viton